Value Added Assemblies & Stampings

Alpha’s design team is experienced in engineering a variety of stamped products to meet your specific needs. We are equipped with a range of presses to ensure stamping accuracy, dimensional integrity and fit for purpose – the only standards Alpha accepts in order to exceed full satisfaction of our customers.

- Press capability up to 1,000 ton

- Material capability up to 16mm (5/8”) thickness

- Manufacturing expertise in aluminum, copper, martensite, HSLA

and others - Value-added processes including welding, mechanical or weld attached fasteners, barrier film, thermal insulators and over molding

- In-die staking and assembly capabilities

- Tooling designs for optimal material utilization

- Cost effective light weighting designs to targeted product strengths

- High, medium and low volume solutions

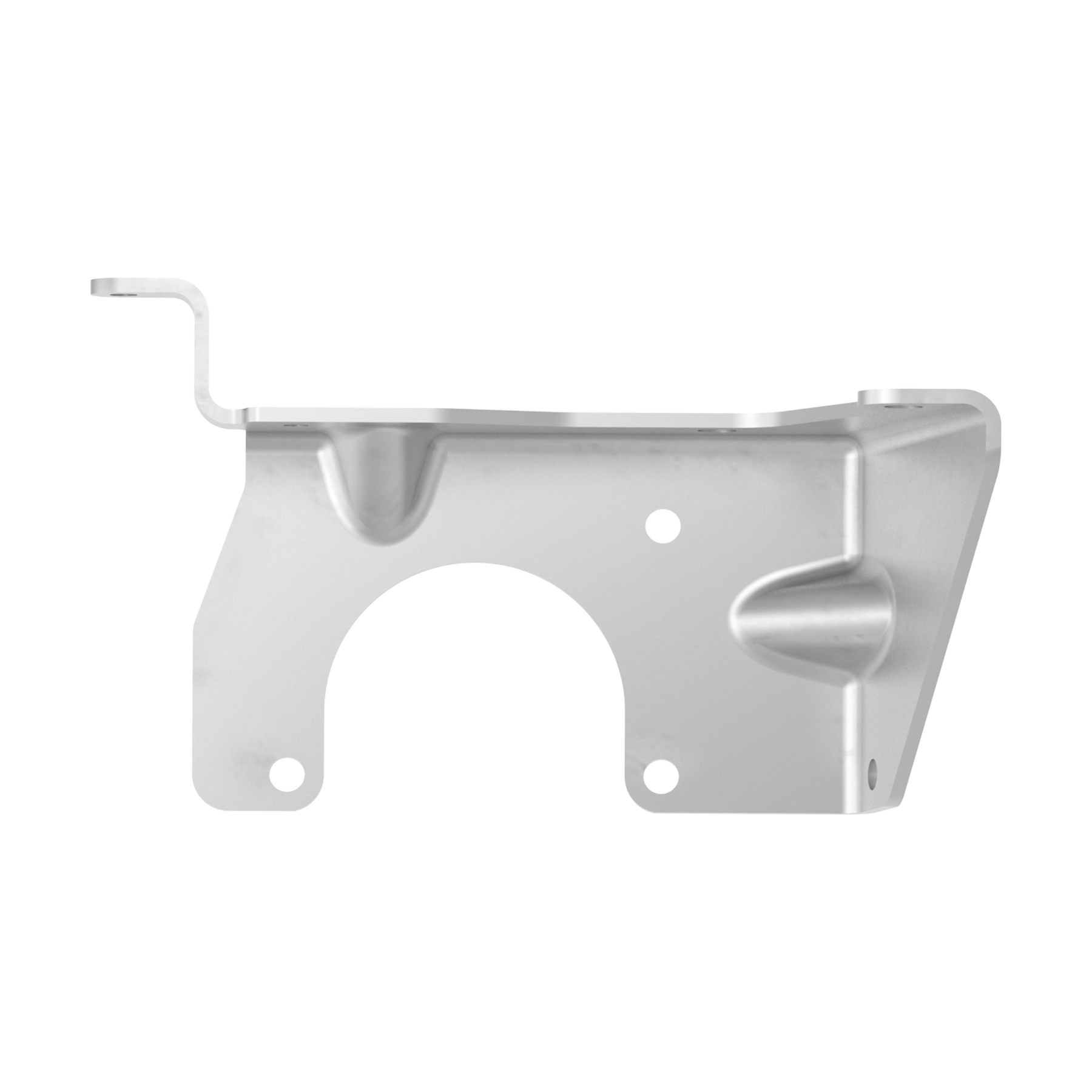

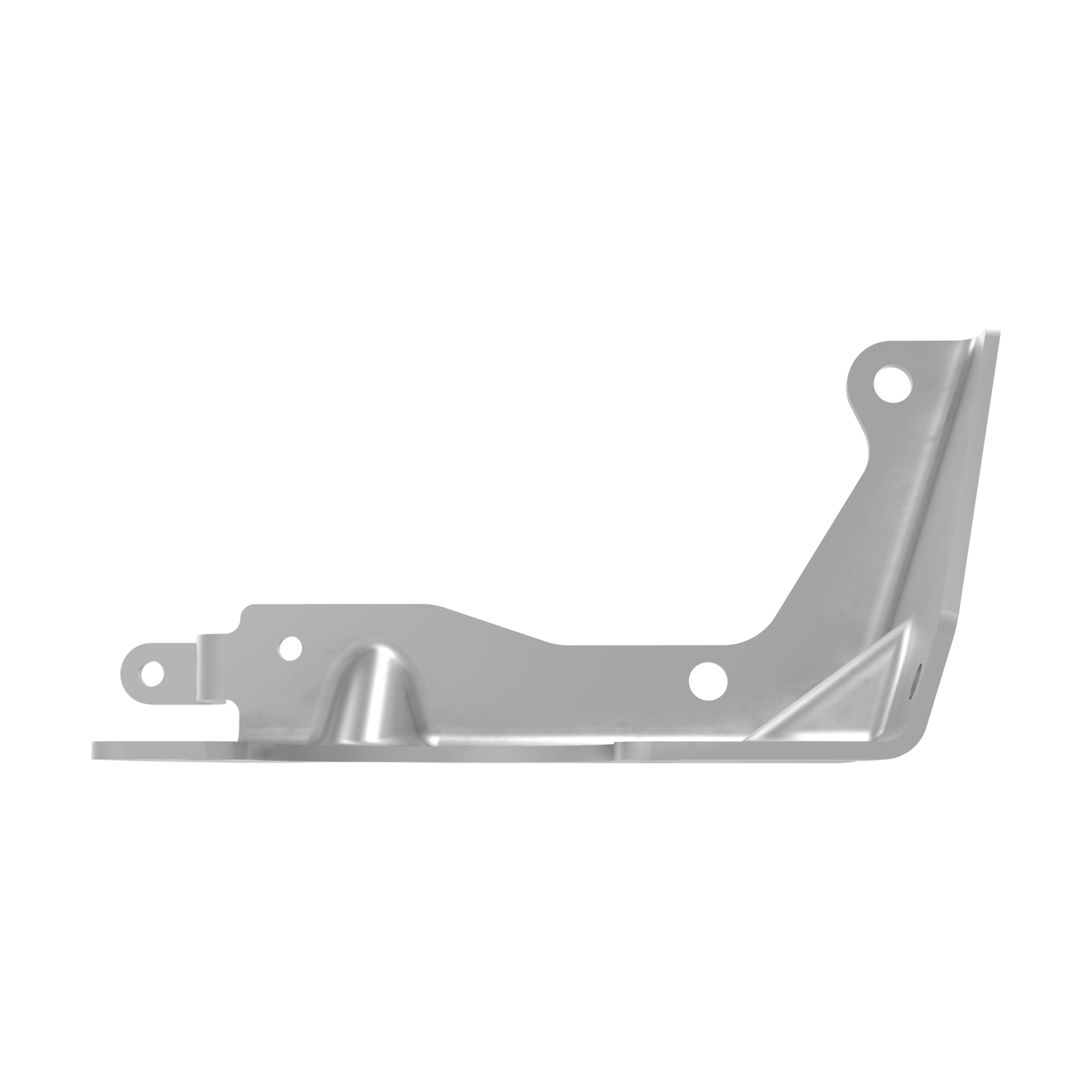

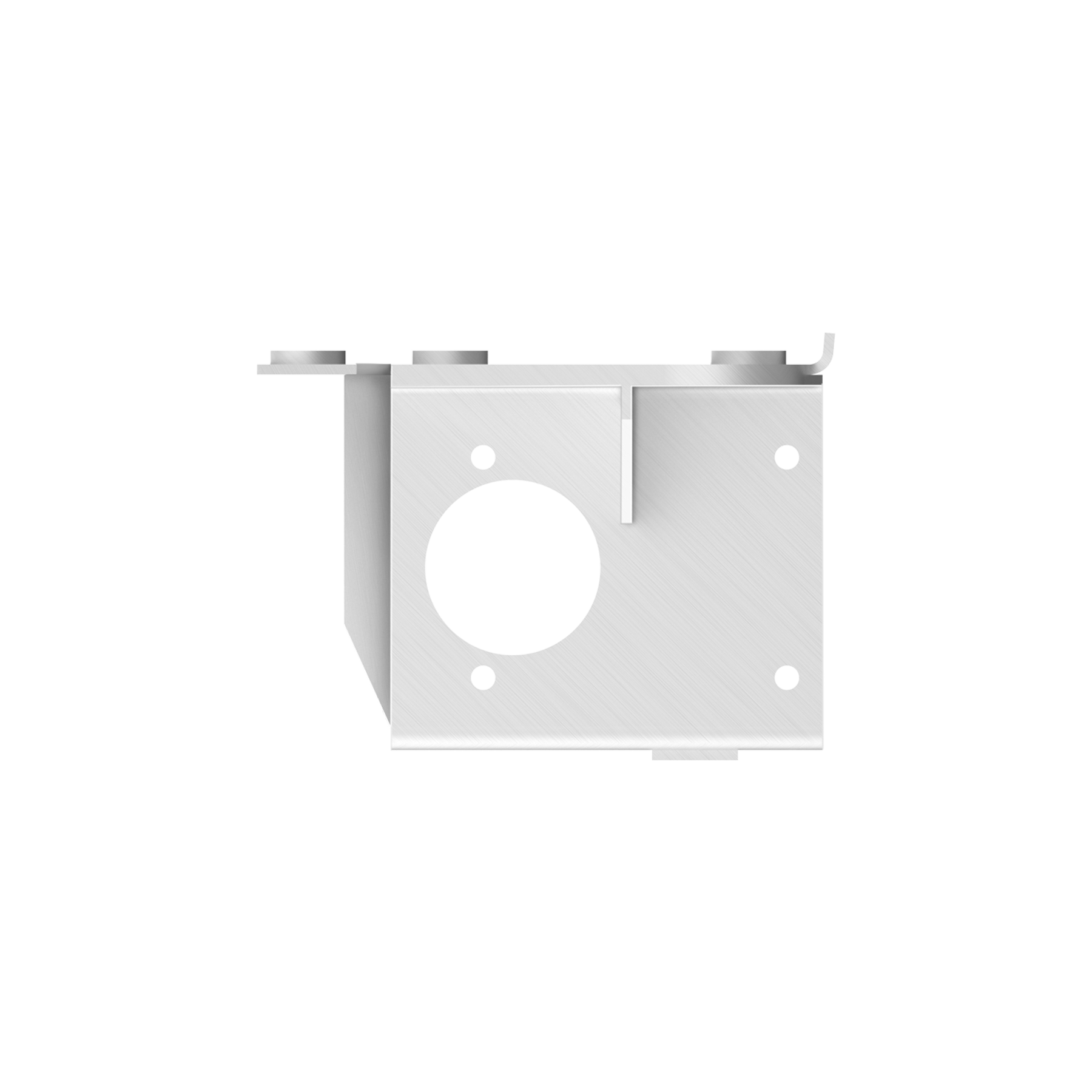

Leaf Spring Seat

Alpha’s redesign of the leaf spring seat to a stamped metal product from forged increased production speed and light weighted the part by approximately 1 lb/piece or 2 lbs/axle. For all solid rear axle vehicles, ask about our family of leaf spring seats in various heights and material thicknesses.

Isometric

Back

Top

Side

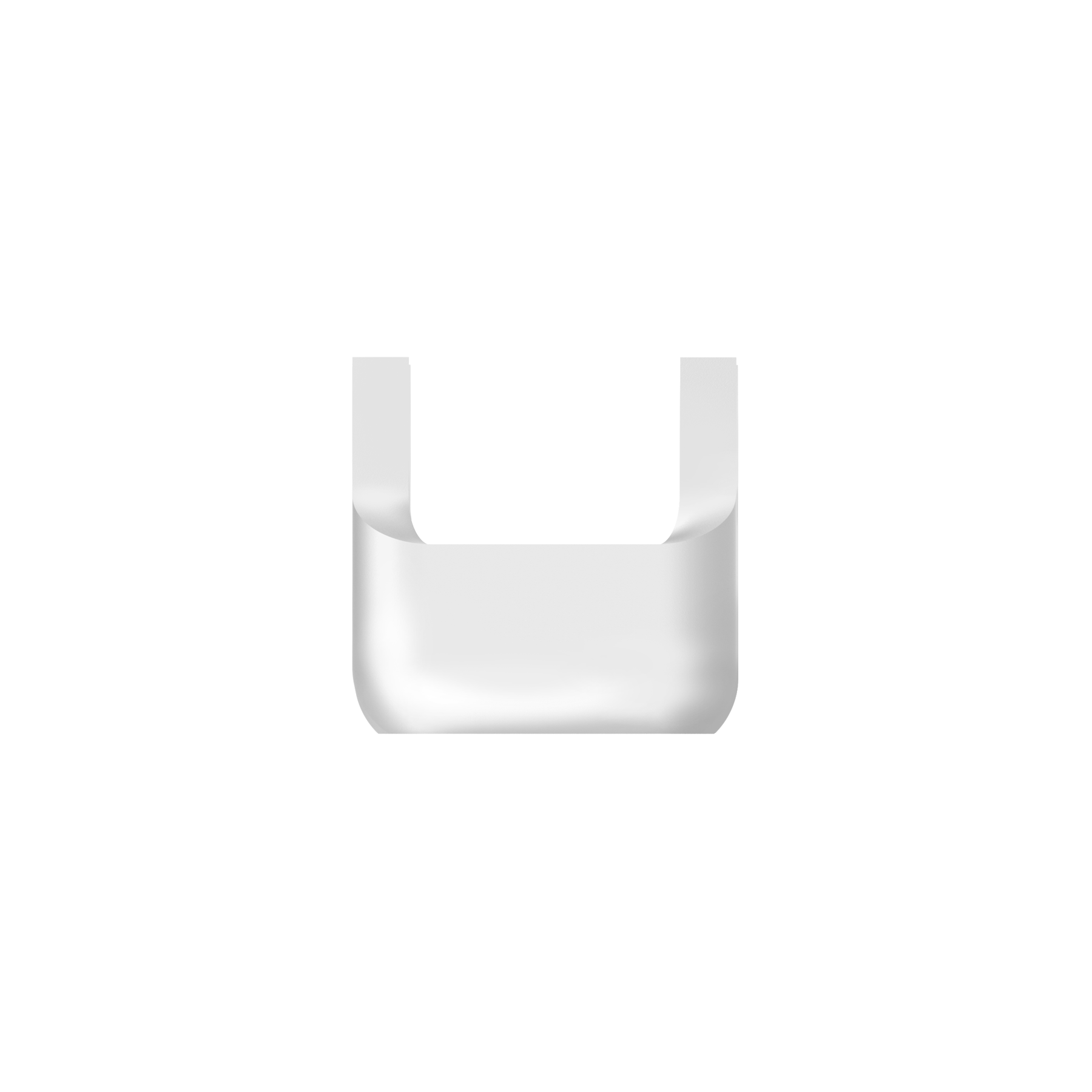

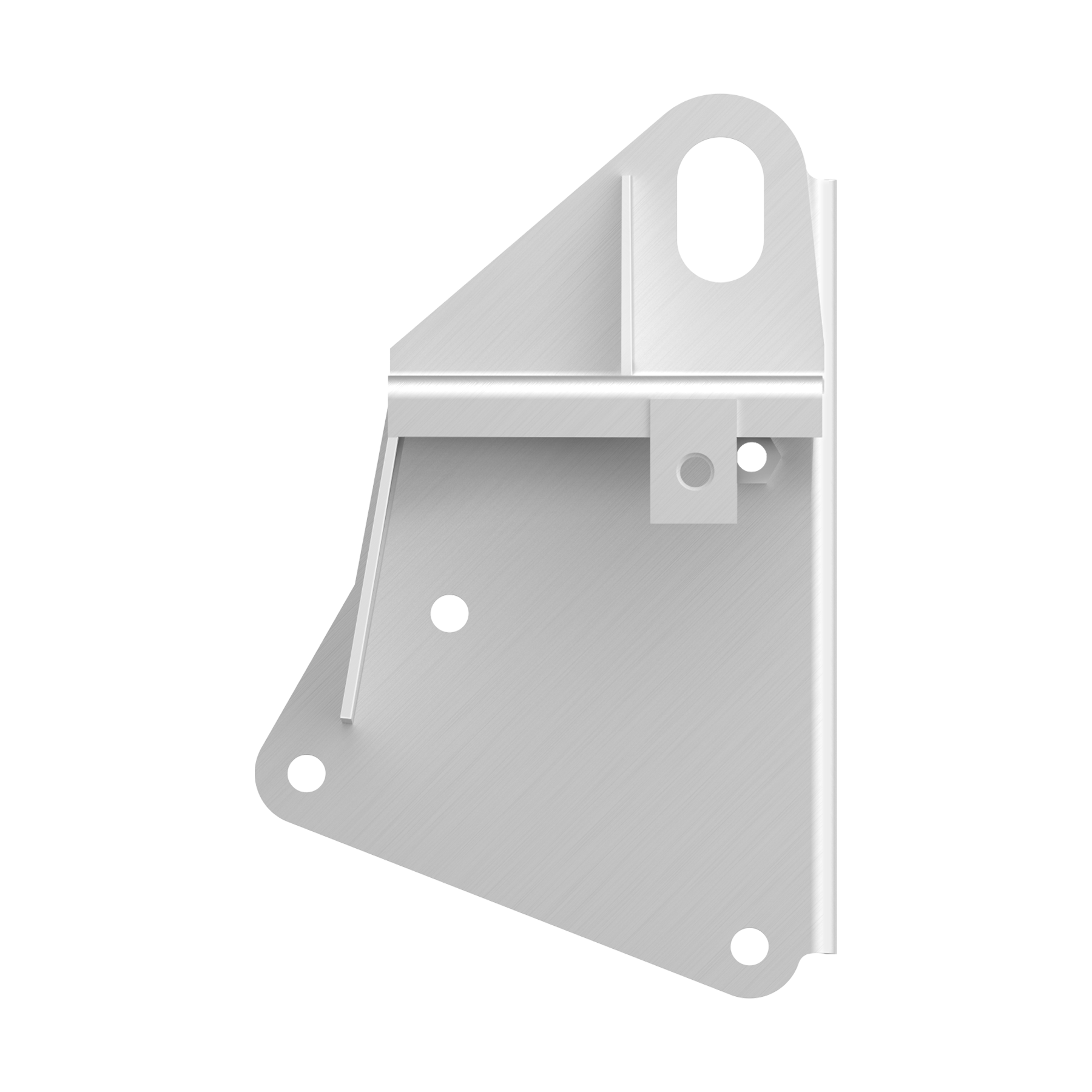

Specialty Mounting Bracket

When metal stampings require multiple specialty features, Alpha’s value added processes include welded on spacers and standoffs, weld studs, weld nuts, anti-rotation tabs and plastic over molding or plastisol features.

Isometric

Front

Top

Side

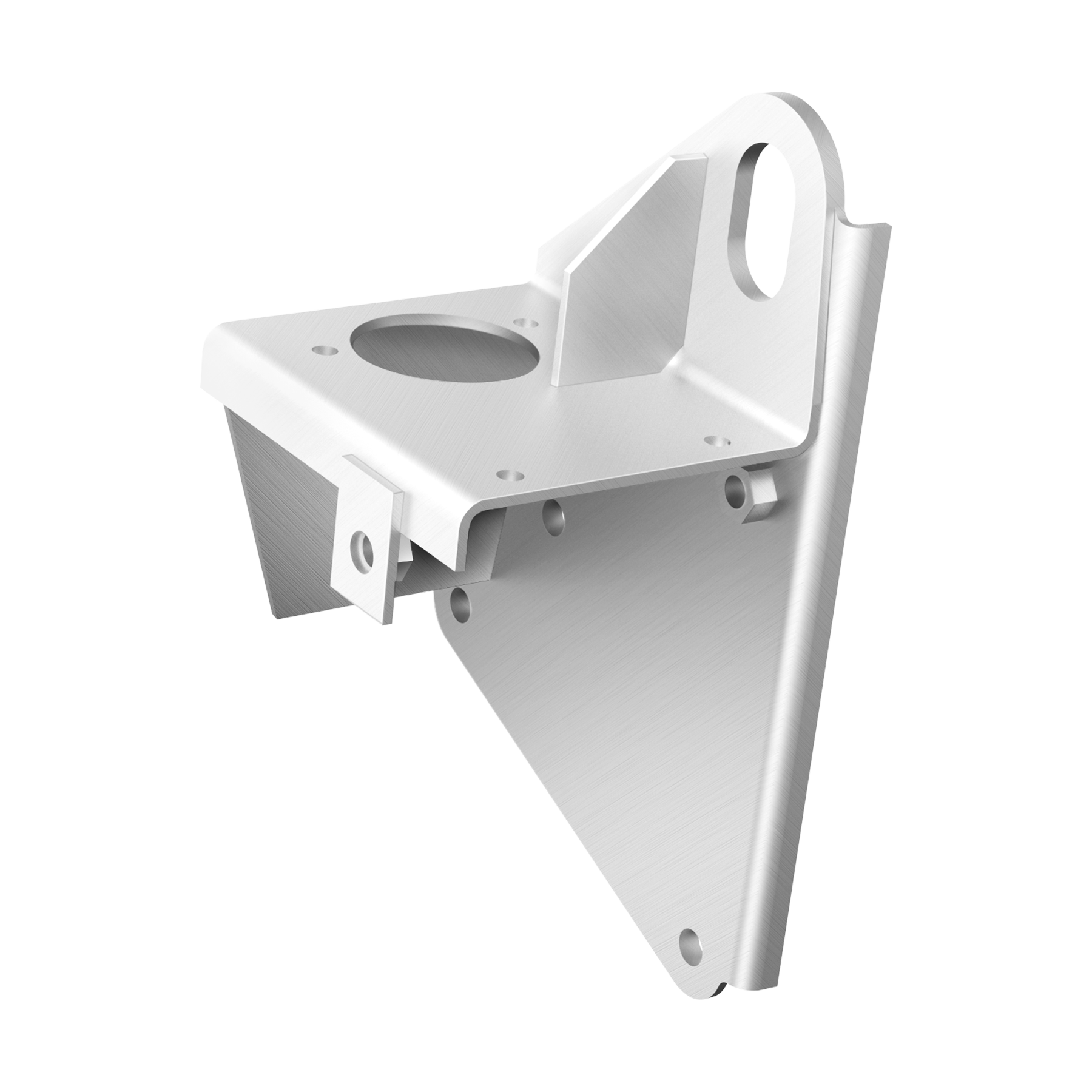

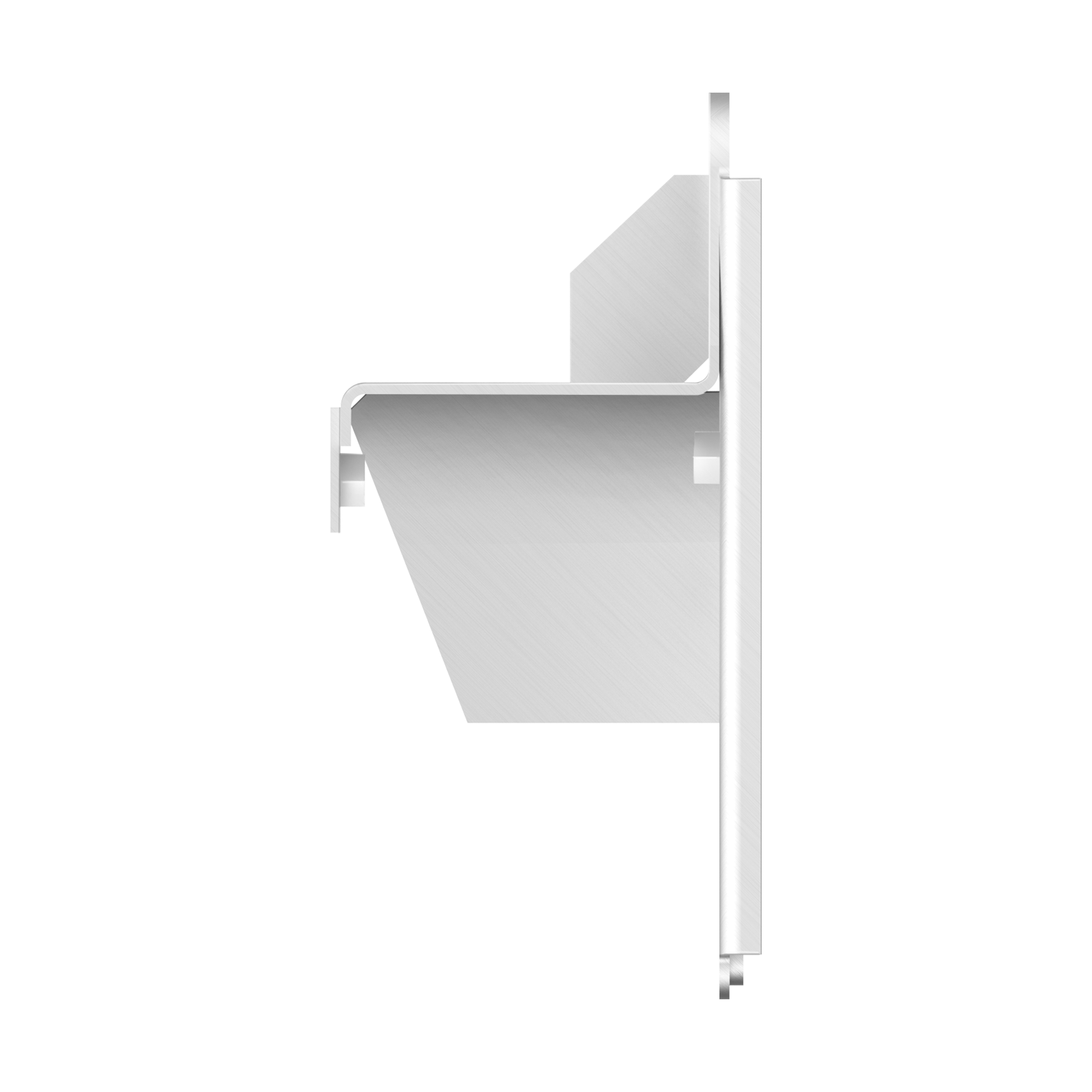

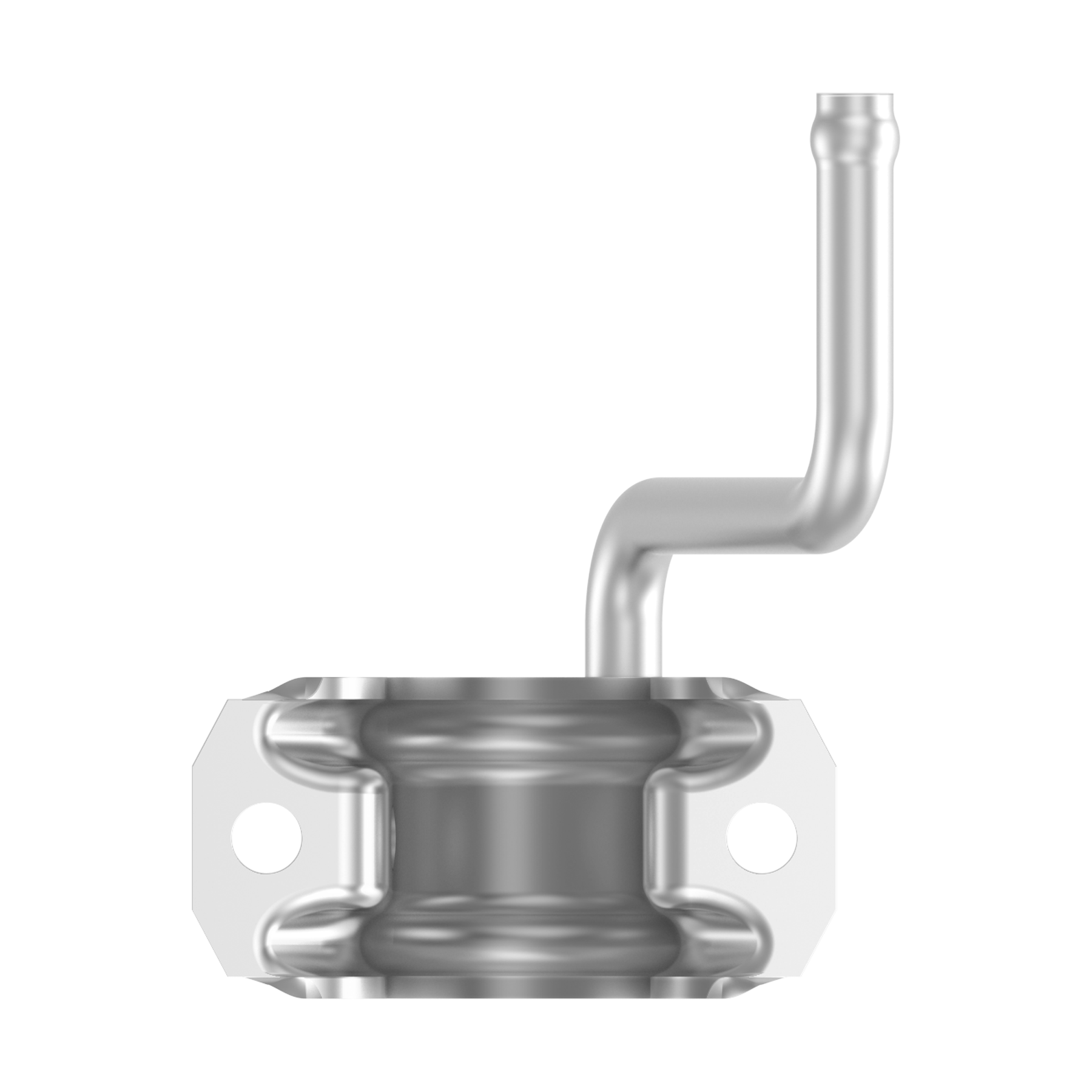

Turbocharger Bracket

Alpha’s expertise in custom welded fabrications is exemplified by the turbocharger bracket. By varying material types and thicknesses, Alpha created a mounting bracket that is lightweight yet extremely durable for use in extreme duty applications.

Isometric

Side

Top

Front

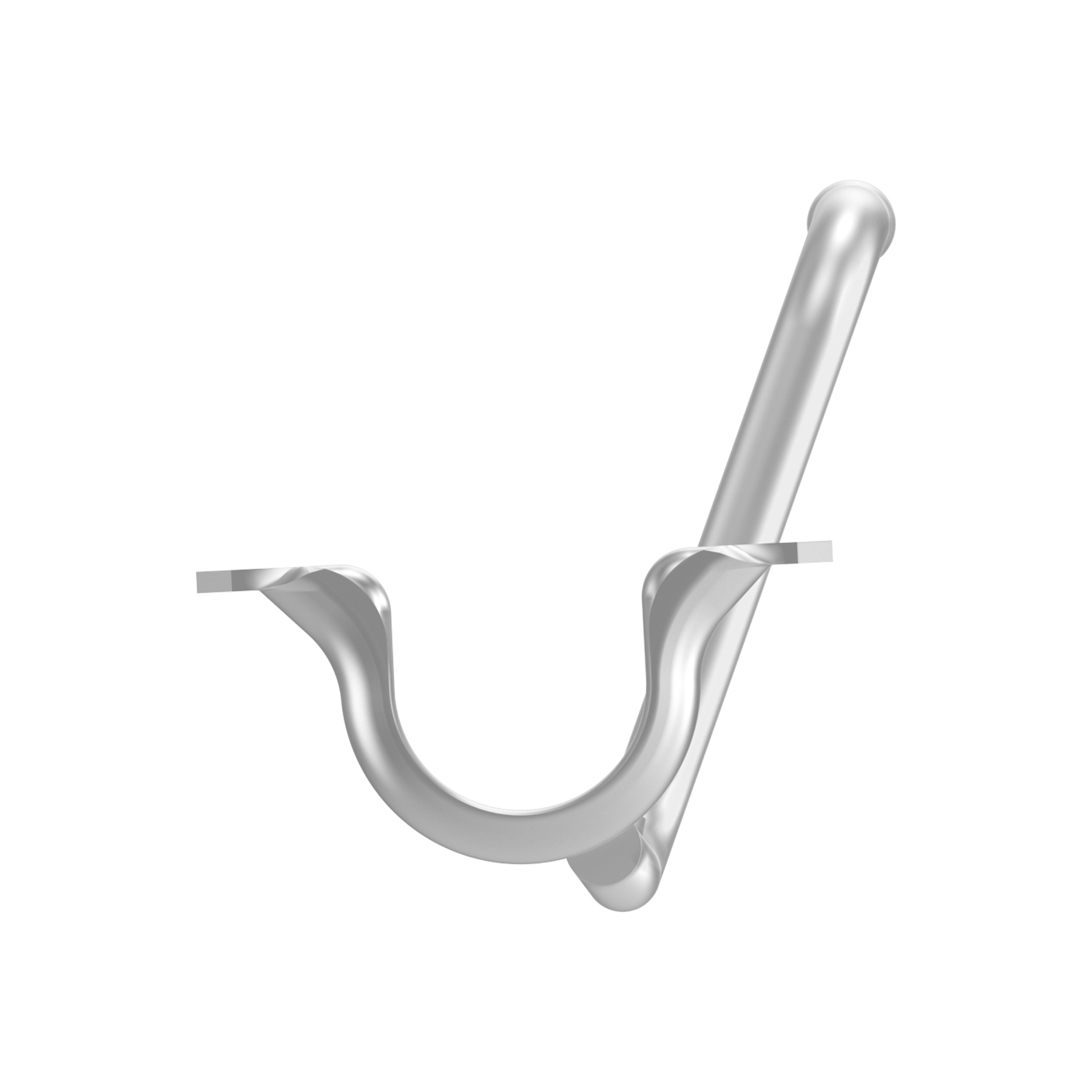

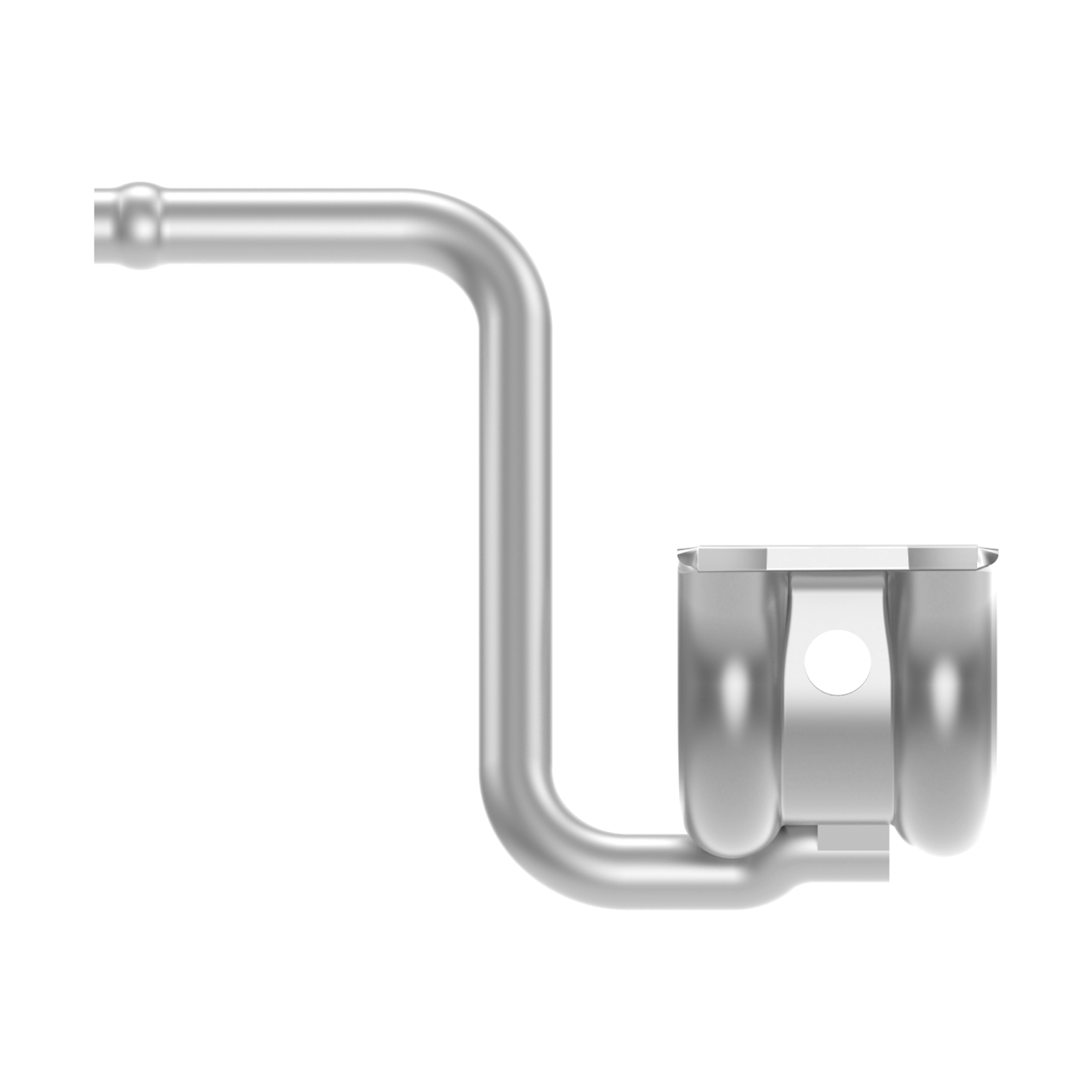

Off-Road Sway Bar Assembly

The challenge in welding a thin stamped bracket to a thick formed bar is in maintaining the correct spatial orientation after part cooling. Alpha has vast experience in accurately welding materials with extreme variation in thickness, and designed a process for doing so in this Off Road Sway Bar Assembly.

Isometric

Front

Top

Side

or

Please call 734-523-1000